-

High Light

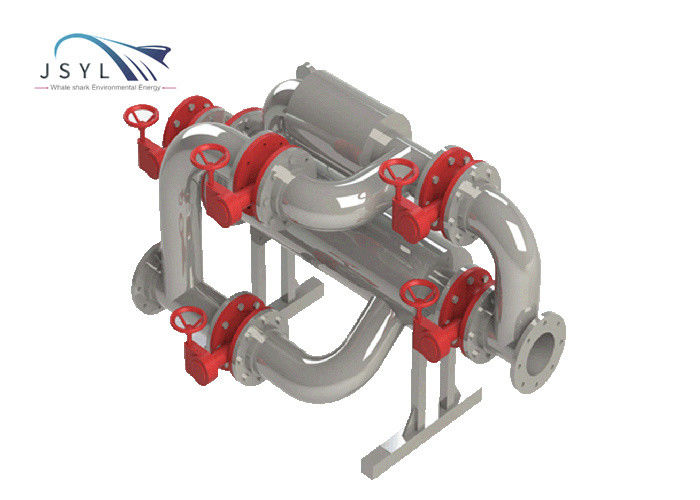

304 Stainless Steel Duplex Filter

,500m3/H duplex filter

,1m3/H Manual Backwash Strainer

-

Product NameDuplex Filter

-

OriginHebei China

-

Applicable IndustriesPower Plants, Steel Mills, Paper Industry, Industry, Chemical Industry, Food And Water Industry

-

Pressure1.0-4.0MPa

-

Equipment TypeDual-channel Filtration And Mutual Automatic Anti-cleaning

-

Shell MaterialCarbon Steel/304

-

Flow1~500m3/h

-

Filter Element Material304 Stainless Steel

-

Micron Grade1-3000 Microns

-

Connection TypeFlange And Thread

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

1-500m3/H 304 Stainless Steel Duplex Filter Manual Backwash Strainer

Manual duplex filter

Introduction

The dual complementary backwash filter uses physical action to separate and recover the insoluble and suspended pollutants in the wastewater (including particulate debris and solid oil). According to the different sewage, our filter is equipped with different packages. The filter element achieves the best effect of sewage treatment.

Advantage

<1> Revolutionary dual channel

<2> Dual-channel filtration and mutual backwashing

<3> Filter element backwashing (lower maintenance cost)

<4> Living components, easy to replace and easy to maintain

<5> High filtration accuracy (1-3000 microns)

<6> Intelligent control system

| FILTER SPECIFICATION TABLE | ||||||||

| Model |

Pipe diameter (Inch) |

Inlet and outlet (DN) |

Filtered water M3(H) |

long (mm) |

width (mm) |

high (mm) |

weight kg |

Filtration accuracy (um) |

| JSYL-S5-DN20 | 0.6 | 20 | 2.1 | 750 | 130 | 450 | 15 | 1-3000 |

| JSYL-S5-DN25 | 1 | 25 | 3.8 | 780 | 150 | 490 | 18 | 1-3000 |

| JSYL-S5-DN40 | 1.5 | 40 | 8 | 920 | 180 | 510 | 25 | 1-3000 |

| JSYL-S5-DN50 | 2 | 50 | 15 | 1150 | 220 | 620 | 38 | 1-3000 |

| JSYL-S5-DN65 | 2.5 | 65 | 25 | 1260 | 295 | 880 | 55 | 1-3000 |

| JSYL-S5-DN80 | 3 | 80 | 40 | 1370 | 360 | 1100 | 75 | 1-3000 |

| JSYL-S5-DN100 | 4 | 100 | 70 | 1575 | 480 | 1300 | 150 | 1-3000 |

| JSYL-S5-DN125 | 5 | 125 | 100 | 1860 | 550 | 1450 | 300 | 1-3000 |

| JSYL-S5-DN150 | 6 | 150 | 145 | 2160 | 620 | 1568 | 480 | 1-3000 |

| JSYL-S5-DN200 | 8 | 200 | 238 | 2320 | 810 | 1610 | 800 | 1-3000 |

| JSYL-S5-DN250 | 10 | 250 | 380 | 2540 | 1300 | 2050 | 1000 | 1-3000 |

| JSYL-S5-DN300 | 12 | 300 | 500 | 2760 | 1400 | 2180 | 1200 | 1-3000 |

![]()

Application industry:

1. Petrochemical industry: oil well water injection, process circulating water, cooling water filtration; lubricating oil, jet fuel and other oil filtration.

2. Fine chemicals: filter resin raw materials, remove fibers, gels, and filter solvents in paint; large impurity particles in the ink, and particles that are not up to the standard grinding fineness, remove agglomerated impurities after mixing and reaction; filter adhesives and fillers Of large particles of carbon black.

3. Industrial manufacturing: lubricating oil filtration, cooling water circulation filtration, heavy metal recovery filtration, ultra-fine grinding oil filtration, cutting fluid, cleaning fluid, filtration of impurities in recovery; used in raw material fields, sintering pellet plants, blast furnaces, rolling mills, continuous Water treatment filtration for cooling water filtration of casting machines and other systems.

4. Papermaking industry: various papermaking water filtration, raw water filtration, high and low pressure spray water, spray water, white water, sealing water, bearing cooling water, cooling tower water, high and low pressure clean water, etc., paper coating filter aid, polymer , Bentonite, starch liquid, defoamer, sizing agent, lubricant, water repellent, fuel, filler, pigment, calcium carbonate, latex, etc.

filter.

5. Mine: Filter underground sprinkling water to ensure the normal operation of the system.

6. Power plant: the precision pretreatment part used for the preparation of high-purity water in power plant boilers, the filtration of generator cooling water and sealing water;

7. Agricultural garden: In sprinklers and sprinkler systems, equipment blockage and wear caused by impurities should be reduced. Therefore, high-precision, highly automated filtration products must be selected to ensure the normal operation of the sprinkler irrigation system.