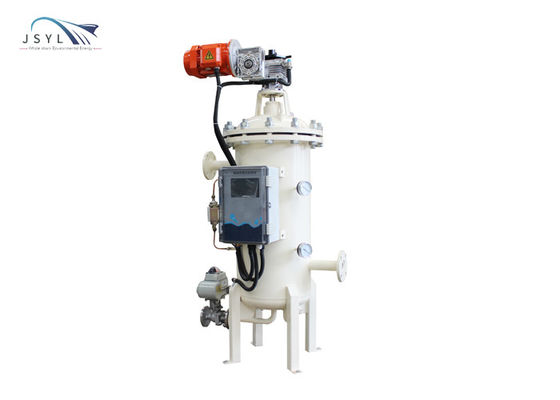

Stainless steel solid-liquid separator for chemical industry

Introduction

The liquid enters the body filter from the inlet, and the liquid is filtered by the filter element. The impurities in the liquid are deposited on the stainless steel filter screen. When the inlet pressure and the outlet pressure reach the set value; the system automatically starts the backwash procedure; the sensor transmits the information To the power distribution system, the power distribution system receives the pressure signal to trigger: the backwashing rotating arm rotates; and then the filter element is recoiled one by one; under the action of the pressure difference, the dirt inside the filter element is washed away and discharged through the sewage outlet;

Technical characteristics

1. Automatic continuous online filtration, without interrupting the flow during backwashing, reducing downtime and maintenance costs;

2. The filter screen has high filtration accuracy, high backwashing efficiency, and high structural strength; the service life of the shell is more than 10 years;

3. Water enters at both ends of the filter to increase the flux of the filter cartridge; the free flow of water can delay the surface blockage and avoid the blockage of one end of the filter;

4. Filter element recoil, after aligning the filter element, open the drain valve to recoil, the backwash intensity is high, the effect is good, the time-consuming is short, and the liquid is saved

5. Compact design, large flux, greatly saving installation space and construction cost;

6. The automatic control system has high reliability; the interface is intuitive and easy to operate efficiently according to actual working conditions.

| PRODUCT PARAMETER | |

| Specifications | Equipment parameters |

| Equipment model |

DN25, DN40, DN50, DN100, DN150, DN200, DN250, DN300, DN400, DN500, DN600, DN700, DN800, DN900, DN1000 |

| Applicable liquid | water and low viscosity liquid (˂40cps); impurity level˂300ppm |

| Minimum work |

pipeline pressure difference>0.15MPa

|

| Filter accuracy | 10-2,000μm |

| Design pressure | 0.5/1.0/1.6/2.0/4.0MPa (higher pressure can be customized.) |

| Design temperature | 0-95°C |

|

Single filter area

|

0.45m2-14.40m2 |

| Cleaning pressure drop | 0.05-0.1MPa |

| Control system | Pressure difference and time parallel control |

| Indicator | Differential pressure transmitter |

| Gear motor | Three-phase power supply, 380V, protection grade IP55; worm gear reducer |

| Import and export size | 2"-24" |

| Main body material | carbon steel/304 |

![]()

![]()

![]()

![]()

Applicable industries:

Petrochemical pipelines, energy chemical pipelines, fine chemical pipelines