-

High Light

Duplex Automatic Backwash Strainer

,Industrial automatic backwash strainer 1.0Mpa

,Industrial backwash strainer 4.0MPa

-

Product NameDuplex Filter

-

OriginHebei China

-

Micron Grade1 Microns To 3000 Microns

-

Flow1~500m3/h

-

Applicable IndustriesPower Plants, Steel Mills, Paper Industry, Industry, Chemical Industry, Food And Water Industry

-

Equipment TypeDual-channel Filtration And Mutual Automatic Anti-cleaning

-

Filter Element Material304 Stainless Steel

-

Pressure1.0-4.0MPa

-

Shell MaterialCarbon Steel/304

-

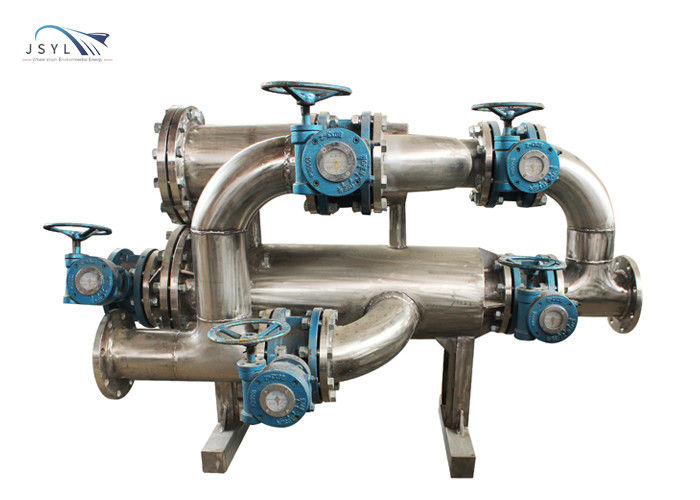

Connection TypeFlange And Thread

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

Industrial Duplex Automatic Backwash Strainer 1.0-4.0MPa

Industrial Duplex Filter

Introduction

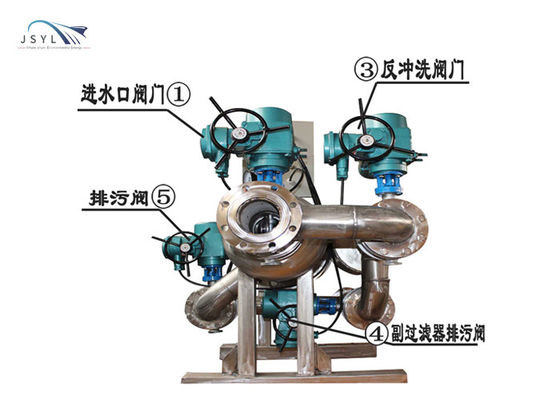

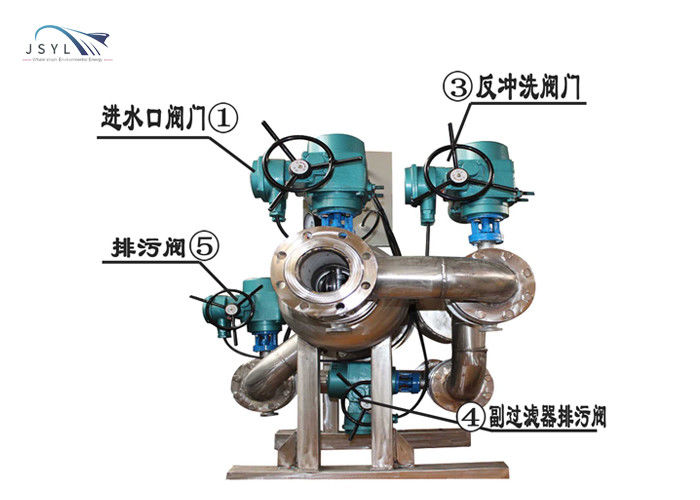

The filter is composed of dual channels, and the water enters the main filter from the water inlet to filter. When the pressure of the water inlet and the pressure of the water outlet are ≥0.05Mpa; the system automatically starts the backwashing program; the dual-channel filter automatically backwashes each other; it has been filtered The pipes should be backwashed with water; to achieve backwashing without leaving dead corners and completely unblocked; the filtering accuracy can reach up to 1um.

Advantage

1. Fully automatic intelligent control

2. Small size, large flow, high precision

3. Intelligent online backflushing does not stop and flow continuously;

4. The body replaces the filter element, quick-plug design, easy to replace;

5. Multi-filter element structure; precision can be adjusted;

6. It can be installed vertically/horizontally, which significantly saves installation space

7. The filter element has an online recoil precision of 5 microns, which can be used repeatedly.

| FILTER SPECIFICATION TABLE | ||||||||

| Model |

Pipe diameter (Inch) |

Inlet and outlet (DN) |

Filtered water M3(H) |

long (mm) |

width (mm) |

high (mm) |

weight kg |

Filtration accuracy (um) |

| JSYL-S5-DN20 | 0.6 | 20 | 2.1 | 750 | 130 | 450 | 15 | 1-3000 |

| JSYL-S5-DN25 | 1 | 25 | 3.8 | 780 | 150 | 490 | 18 | 1-3000 |

| JSYL-S5-DN40 | 1.5 | 40 | 8 | 920 | 180 | 510 | 25 | 1-3000 |

| JSYL-S5-DN50 | 2 | 50 | 15 | 1150 | 220 | 620 | 38 | 1-3000 |

| JSYL-S5-DN65 | 2.5 | 65 | 25 | 1260 | 295 | 880 | 55 | 1-3000 |

| JSYL-S5-DN80 | 3 | 80 | 40 | 1370 | 360 | 1100 | 75 | 1-3000 |

| JSYL-S5-DN100 | 4 | 100 | 70 | 1575 | 480 | 1300 | 150 | 1-3000 |

| JSYL-S5-DN125 | 5 | 125 | 100 | 1860 | 550 | 1450 | 300 | 1-3000 |

| JSYL-S5-DN150 | 6 | 150 | 145 | 2160 | 620 | 1568 | 480 | 1-3000 |

| JSYL-S5-DN200 | 8 | 200 | 238 | 2320 | 810 | 1610 | 800 | 1-3000 |

| JSYL-S5-DN250 | 10 | 250 | 380 | 2540 | 1300 | 2050 | 1000 | 1-3000 |

| JSYL-S5-DN300 | 12 | 300 | 500 | 2760 | 1400 | 2180 | 1200 | 1-3000 |

![]()

Application industry:

1. Food and beverage: security filtration before filling; industrial food production process water; syrup and other raw material filtration; removal of impurities generated in the blending process; process filtration of chocolate, jelly, beer, etc.; filtration of suspended solids and sediments in beverages .

2. Automobile manufacturing, electrophoresis paint, metal paint, varnish filtration; engine processing coolant filtration; welding part cooling water filtration; electronics industry pure water; removal of impurities in the copper foil electrolytic stabilization tank, wafer cutting and grinding wastewater circulation filtration;

3. Water quality treatment: filtration of sand, algae and silt deposits in raw water; filtration of steel industry, air conditioning systems, compressor circulating cooling water and frozen water; filtration of removing scale and calcification in water pipes; pre-filtration of membrane purification liquid , Intercept ion exchange resin and so on.

4. Energy and chemical industry: The traditional energy chemical industry is a high-consumption, high-emission, and high-pollution industry; to solve the environmental protection problems of energy and chemical industry, the first thing to do is to solve the problems of recycling and recycling of sewage and discharge management in the production process; so industrial sewage Treatment and sewage recycling are the goals pursued by the company; the dual-pass complementary backwash filter has achieved the goals pursued by energy and chemical companies.

5. Petrochemical industry: oil well water injection, process circulating water, cooling water filtration; lubricating oil, jet fuel and other oil filtration.

6. Fine chemical industry: Resin raw material filtration, remove fibers, gels, and filter solvents in paint; large particles of impurities in ink and particles of substandard grinding fineness, remove agglomerated impurities after mixing reaction; filter large particles of carbon black in adhesives And filler.