DN50 1.6MPA Low Pressure Water Filter Multi Core Backwash Filter

-

High Light

1.6MPA Low Pressure Water Filter

,DN50 Low Pressure Water Filter

,DN50 Multi Core Backwash Filter

-

Product NameLow Pressure Series Water Filter

-

OriginHebei China

-

Applicable IndustriesManufacturing Plants, Food And Beverage Plants, Farms, Restaurants, Energy And Mining, Food And Beverage Stores

-

Warranty ServiceVideo Technical Support, Online Support Maintenance And Repair Services

-

Core ComponentsPLC, Motor, Filter Element, Valve

-

Warranty1 Year

-

FilterSintered Filter

-

ApplicationWater Treatment, Papermaking, Chemicals, Power Plants, Steel Plants, Etc.

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

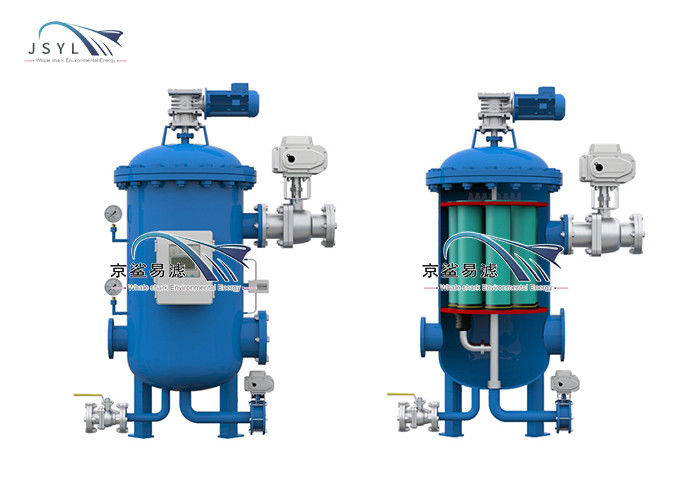

DN50 1.6MPA Low Pressure Water Filter Multi Core Backwash Filter

DN50-1.6MPA automatic multi-core backwash filter

Product Description

The JSYL series of multi-core backwash filters are equipped with an automatic cleaning control system, integrated pressure difference control and time control parallel control functions, which can control the filter to operate efficiently according to the working conditions, and the intelligent control can be remote; it supports on-site control and adjustment.

Applicable liquid types: ground water, sea water, lake water, reservoir water, pond water, circulating cooling water, chilled water, high and low pressure spray water, water needle water, heat exchange water, sealing water, bearing cooling water, oil well water injection, process circulating water , Machining coolant, cleaning agent, cleaning water, etc.

Advantage

1. Automatic continuous online filtration, without interrupting the flow during backwashing, reducing downtime and maintenance costs;

2. The filter screen has high filtration accuracy, high backwashing efficiency, and high structural strength; the service life is more than 10 years;

3. Pulse backwashing; after aligning the filter element, open the drain valve; backwashing intensity is high, the effect is good, and it saves time and water;

4. Water enters at both ends of the filter to increase the flux of the filter cartridge; the free flow of water can delay the blockage of the surface and avoid the blockage of one end of the filter;

5. Compact design, large flux, greatly saving installation space and construction cost;

6. Highly integrated, no need for a large number of automatic valves, joints, and seals, high reliability and low operating cost;

7. The automatic control system has high reliability; the interface is intuitive and easy to operate efficiently according to actual working conditions.

| PRODUCT PARAMETER | |||

| Shell selection | Carbon steel/stainless steel | Filter element form |

Wedge wire gap type Multi-layer woven mesh sintered |

| Single machine flow | 5-8m3/h | Number of filter elements | 5-6 core |

| Preset pressure |

1.6MPa

|

Filtration accuracy |

50 microns

|

| Applicable viscosity | 1-40cp | Applicable temperature | 0-95°C |

| Operation mode | Fully automatic intelligent control | Power supply | 380V, 50Hz/ 220v |

| Backwash components | 304 stainless steel | Filter element design | Detachable replacement |

| Power machine | Compound reducer | Position proximity switch | Inductive |

| Backwash node | Seven Star Node Disk | Pressure gauge | Anti-vibration pressure gauge |

| Filter replacement cycle | Half a year / more than one year | Installation method | Vertical installation/horizontal installation |

![]()

![]()

![]()

Applicable industry

Applicable liquid types: ground water, sea water, lake water, reservoir water, pond water, circulating cooling water, chilled water, high and low pressure spray water, water needle water, heat exchange water, sealing water, bearing cooling water, oil well water injection, process circulating water , Machining coolant, cleaning agent, cleaning water, etc.