-

High Light

DN50 backwash filtration system

,Horizontal Backwash Filtration System

,Carbon Steel horizontal backwash filter

-

Product NameAutomatic Backwash Filter System

-

OriginHebei China

-

Applicable IndustriesCondition: New Applicable Industries: Manufacturing Plants, Food And Steel Plants, Power Plants And Mining Warranty Service: Online Support Marketing Type: 2020 New Products Core Component Warranty: 1 Year Core Components: Backwash Components Origin: Hebei

-

Core ComponentsBackwash Components

-

Work Pressure>0.5mPa

-

Filter Level5-2000 Microns

-

Standard Design Pressure1.0MPa/1.6MPa/2.5MPa, Can Provide Higher Pressure Level

-

Fluid Working Temperature0-95°C

-

Flow Range2-8000m3/h

-

Motor370W, Three-phase, 380V

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

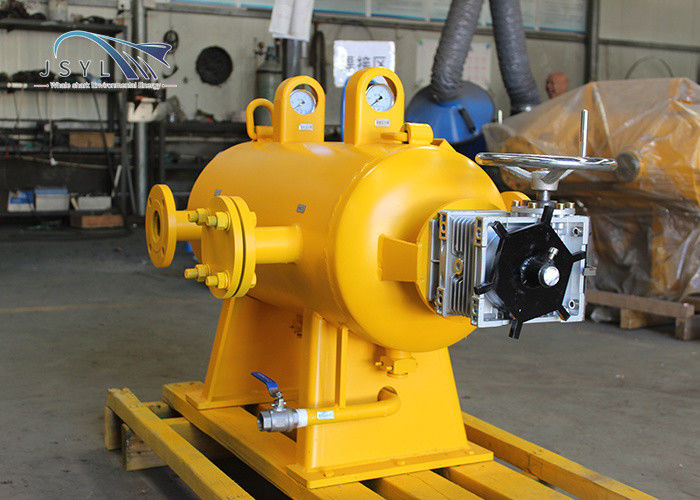

DN50 Carbon Steel Horizontal Backwash Filtration System

DN50 carbon steel horizontal backwash filter

Enterprise Commitment:

Food industry production water and reuse water filtration, production process water supply filtration, equipment cooling water with high water quality requirements; steel, petroleum, chemical, paper, automobile, food, metallurgy and other industries circulating water filtration, reclaimed water reuse, wastewater depth Treatment and filtration, central air conditioning, boiler backwater filtration, groundwater, surface water, swimming pool, landscape water purification and purification, breeding water filtration.

Features:

1. Small size, large flow, high precision

2. Intelligent online backwash without stopping and continuous flow;

3. The body replaces the filter element, quick-plug design, easy to replace;

4. Multi-filter element structure; precision can be adjusted;

5. It can be installed vertically/horizontally, which significantly saves installation space

6. The filter element has an online recoil precision of 5 microns, which can be used repeatedly.

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Equipment model |

JSYL-JDX-ZD-DN50 |

Cleaning method | Equipment's own filter element backwash |

| Shell selection | Carbon steel/stainless steel | Filter element form | Multi-layer woven mesh sintered |

| Single machine flow |

6 m3/h

|

Number of filter elements |

6 elements

|

| Rated pressure | 1.6MPa/2.5MPa/4.0MPa | Filtration accuracy | 40 μm |

| Applicable viscosity (cp) | 1-40cp | Applicable temperature (°C) | 0-95°C |

| Operation mode | Fully automatic intelligent control | Filter element replacement | Large cover flange replacement filter element |

|

Backwashing components

|

304 stainless steel | Filter element design | Cover replacement |

| Power unit | Compound reducer | Position proximity switch | Inductive |

| Backflushing node | Seven-star node disk | Pressure gauge | Seismic pressure gauge |

| Filter replacement cycle | Half a year/more than one year | Installation method | Vertical/Horizontal |

![]()

![]()

![]()

Applicable industry:

Construction circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, paper, food, sugar, pharmaceutical, plastic, automotive industries And other fields.