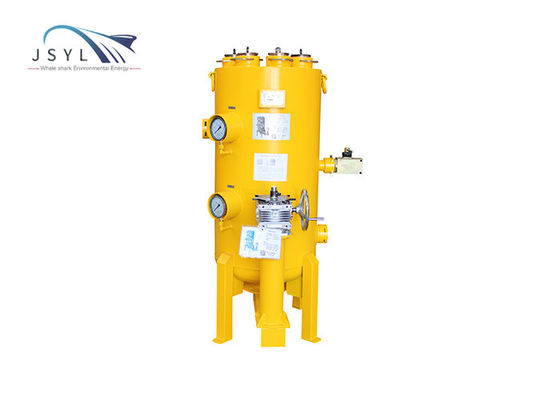

Manual carbon steel multi-core backwash filter

Introduction:

Automatic self-cleaning filter, its internal structure is composed of 304 stainless steel brush, stainless steel filter screen and other main structural parts. The drive motor and electric valve automatically clean and drain. The operation mode is automatic (or manual), with dual functions of differential pressure and automatic sewage discharge. The automation component adopts the most advanced and reliable PLC programmable controller in the world today.

Features:

1. Automatic continuous online filtration, without interrupting the flow during backwashing, reducing downtime and maintenance costs;

2. The filter screen has high filtration accuracy, high backwashing efficiency, and high structural strength; the service life is more than 10 years;

3. Pulse backwashing; after aligning the filter element, open the drain valve; backwashing intensity is high, the effect is good, and it saves time and water;

4. Water enters at both ends of the filter to increase the flux of the filter cartridge; the free flow of water can delay the blockage of the surface and avoid the blockage of one end of the filter;

5. Compact design, large flux, greatly saving installation space and construction cost;

6. Highly integrated, no need for a large number of automatic valves, joints, and seals, high reliability and low operating cost;

7. The automatic control system has high reliability; the interface is intuitive and easy to operate efficiently according to actual working conditions.

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Equipment model |

JSYL-JDX-ZD-DN(25-800) |

Cleaning method | Equipment's own filter element backwash |

| Shell selection | Carbon steel/stainless steel | Filter element form | Multi-layer woven mesh sintered |

| Single machine flow |

2-900 m3/h

|

Number of filter elements |

3-7 elements

|

| Rated pressure | 1.6MPa/2.5MPa/4.0MPa | Filtration accuracy | 10-2000 μm |

| Applicable viscosity (cp) | 1-40cp | Applicable temperature (°C) | 0-95°C |

| Operation mode | Fully automatic intelligent control | Filter element replacement | Large cover flange replacement filter element |

|

Backwashing components

|

304 stainless steel | Filter element design | Cover replacement |

| Power unit | Compound reducer | Position proximity switch | Inductive |

| Backflushing node | Seven-star node disk | Pressure gauge | Seismic pressure gauge |

| Filter replacement cycle | Half a year/more than one year | Installation method | Vertical/Horizontal |

![]()

![]()

![]()

After-sales service:

1. The product implements three guarantees, the quality period is one year, and the technical service is provided for life.

2. The supplier provides the basic drawings of the product and is responsible for providing technical guidance when making the foundation.

3. During the commissioning and equipment commissioning warranty period, if the equipment is damaged due to our responsibility, we will repair and replace it free of charge. If the equipment is damaged due to improper transportation and delivery management, we have the responsibility to cooperate with the buyer. Do a good job in service.

4. After the contract is signed, we will train the demand-side operation and maintenance personnel for free.

5. During the commissioning and equipment commissioning warranty period, if the equipment has quality problems, we guarantee to reply immediately after receiving the notice from the demander, and send technicians to the scene to deal with the problem within 4 hours.