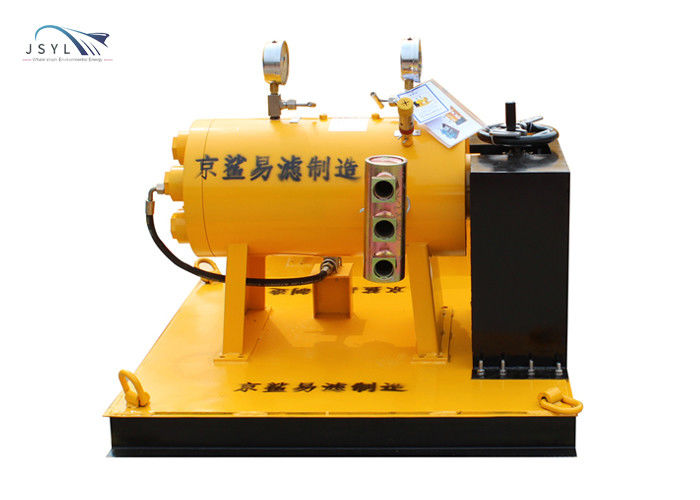

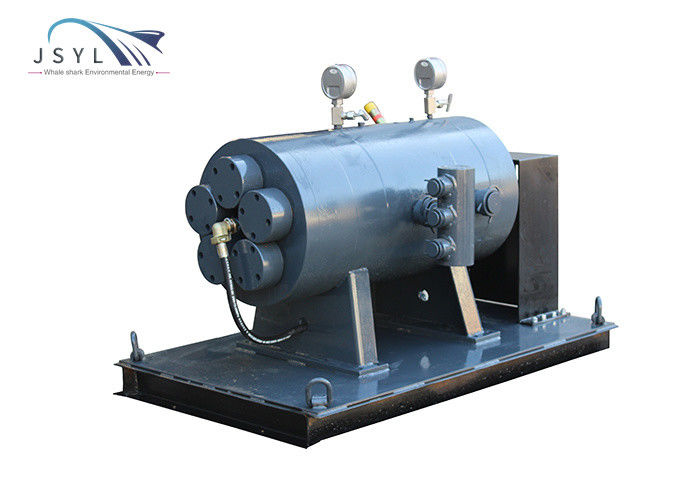

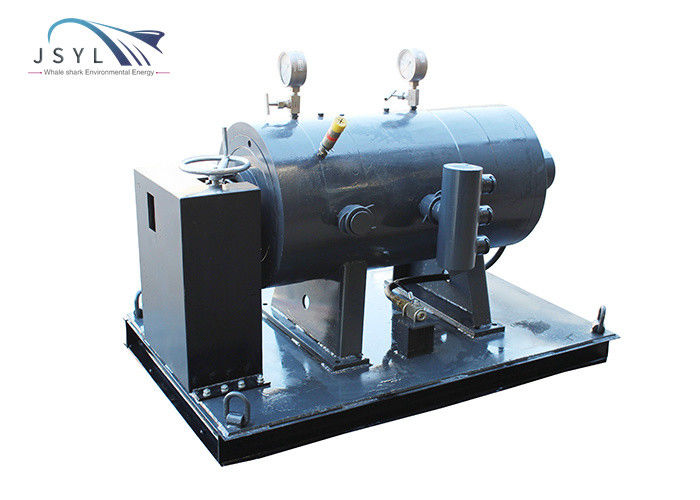

31.5-50MPa 1000L High Pressure Manual Backwash Filter Station

-

High Light

1000L/Min Manual Backwash Filter

,31.5MPa Manual Backwash Filter

,1000L High Pressure Backwash Filter

-

Product NameMining Water Filter

-

OriginHebei China

-

Applicable IndustriesMainly Used In Coal Mine Underground Water Supply System And Make-up Water System

-

Core ComponentsBackwash Filter

-

Warranty1 Year

-

Weight500KG

-

Power200 Watt

-

Shell Material304

-

SurfaceFilter 304

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

31.5-50MPa 1000L High Pressure Manual Backwash Filter Station

1000L manual high pressure backwash filter station

Introduce:

The equipment can meet the cleanliness requirements of the hydraulic fluid for system operation and downstream processes, and can also be used to protect key downstream equipment from particle blockage, abrasion or fouling, improve the operating efficiency and service life of key equipment, and ensure the safe operation of the system. The machine can continuously filter on-line, backflush and discharge the sewage without stopping; continuous flow; high precision; large effective area; high pressure resistance and other advantages.

Principle:

The same equipment can achieve three filtration precisions of coarse, medium and fine; the liquid enters the body through the inlet for filtration, and the impurities are deposited on the stainless steel filter screen. When the inlet pressure and outlet pressure reach the set value; manually open the drain valve and turn the hand wheel of the reducer, As a result, the backwashing node plate rotates 360 degrees, and the high-pressure filter element is sequentially backwashed, and the online backwashing will not stop and flow continuously.

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Equipment model | JSYL-GDX-SD-KJ51/DN50 (Double in and double out) |

Single machine flow |

1000L/Min |

| Shell selection | Alloy steel | Rated pressure | 31.5-50MPa |

| Backwash components |

304 stainless steel

|

Number of filter elements |

A single unit comes standard with 7 high-pressure filter elements

|

| Filter element specification | JSYL-GL-25-350-φ50 | Filtration accuracy | 25μm |

| Pressure gauge | Seismic pressure gauge | Filler replenishment cycle | Replenish once every three months/half a year |

| Operation mode | Manual mechanical operation | Equipment size | 1050*900*1000 |

|

Equipment power supply

|

Voltage 127V | Installation method | Horizontal installation |

![]()

![]()

![]()

Applicable fields:

It is mainly used to filter the emulsion of hydraulic support underground in coal mines, filter out metal particles and rubber impurities of seals in the hydraulic system, and keep the liquid flowing back to the tank clean.