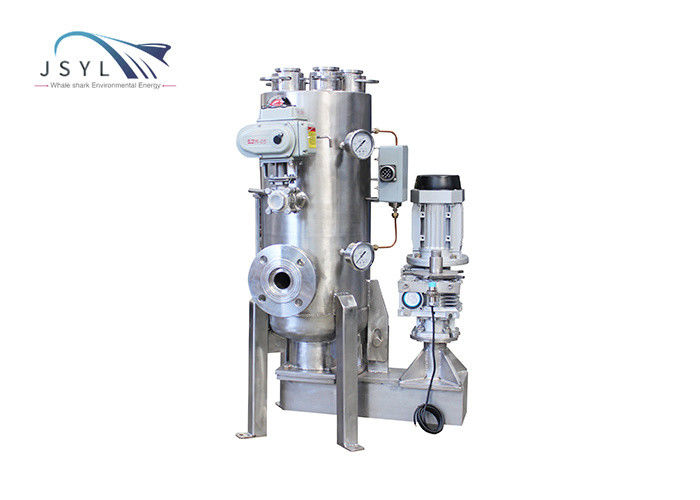

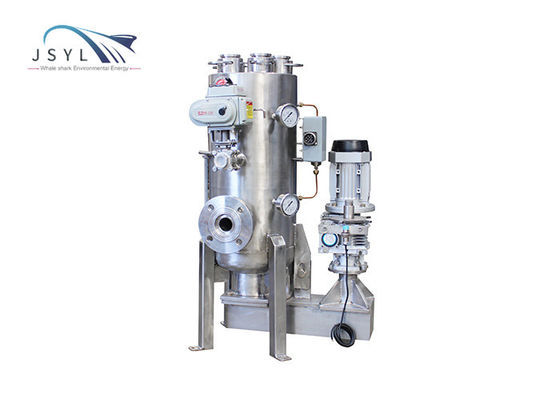

Vertical 1.6MPA Sintered Wire Mesh Filter Backwashing Filter System

-

High Light

1.6MPA Sintered Wire Mesh Filter

,Backwashing Sintered Wire Mesh Filter

,Vertical 1.6MPA backwashing filter system

-

Product NameSintered Wire Mesh Filter

-

OriginHebei China

-

Applicable IndustriesPower Plants, Steel Mills, Paper Industry, Industry, Chemical Industry, Food And Water Industry

-

MaterialSintered Mesh

-

Core ComponentsBackwash Filter

-

UsageLiquid Filter

-

Filter Media304 Stainless Steel Sintered Wire Mesh

-

Installation MethodVertical Or Horizontal

-

Filter Rating100

-

SizeCustom Production

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

Vertical 1.6MPA Sintered Wire Mesh Filter Backwashing Filter System

Sintered wire mesh vertical 1.6MPA backwashing equipment

Describe:

The JSYL series multi-element filter has the characteristics of backwashing and filtering. The machine continuously filters 24 hours a day. Downtime costs, maintenance costs and labor costs are advanced solutions for water and aqueous liquid filtration.

Features:

Automatic self-cleaning filter, its internal structure is composed of 304 stainless steel brush, stainless steel filter screen and other main structural parts. The drive motor and electric valve automatically clean and drain. The operation mode is automatic (or manual), with dual functions of differential pressure and automatic sewage discharge. The automation component adopts the most advanced and reliable PLC programmable controller in the world today.

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Equipment model |

JSYL-JDX-ZD-DN50 |

Cleaning method | Equipment's own filter element backwash |

| Shell selection | Carbon steel/stainless steel | Filter element form | Multi-layer woven mesh sintered |

| Single machine flow |

15 m3/h

|

Number of filter elements |

5 elements

|

| Rated pressure |

1.6MPa/2.5MPa/4.0MPa |

Filtration accuracy | 100 μm |

| Applicable viscosity (cp) | 1-40cp | Applicable temperature (°C) | 0-95°C |

| Operation mode | Fully automatic intelligent control | Filter element replacement | Large cover flange replacement filter element |

|

Backwashing components

|

304 stainless steel | Filter element design | Cover replacement |

| Power unit | Compound reducer | Position proximity switch | Inductive |

| Backflushing node | Seven-star node disk | Pressure gauge | Seismic pressure gauge |

| Filter replacement cycle | Half a year/more than one year | Installation method | Vertical/Horizontal |

![]()

![]()

![]()

Applicable industry:

Construction circulating water treatment, industrial circulating water treatment, sewage treatment, mining industry water treatment, golf course water treatment, construction, steel, petroleum, chemical, electronics, power generation, textile, paper, food, sugar, pharmaceutical, plastic, automotive industries And other fields.