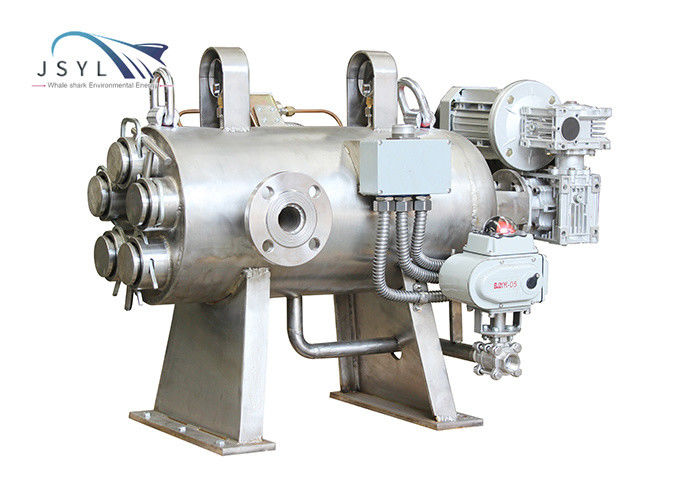

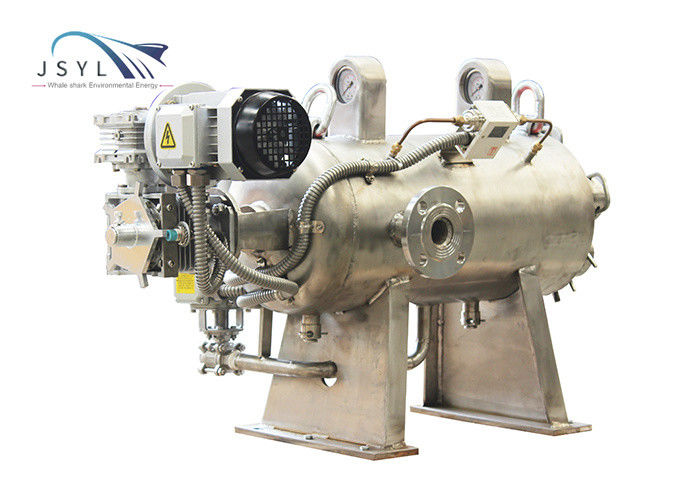

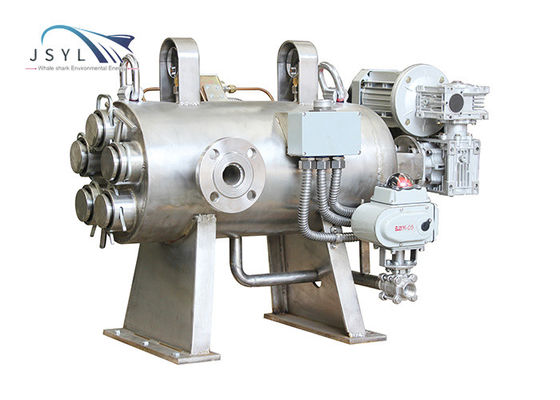

4.0MPa 2000um Sintered Mesh Auto Backwash Strainer For Steel Plant

-

High Light

Sintered Mesh auto backwash strainer

,2000um auto backwash strainer

,4.0MPa automatic backflush filter

-

Product NameSintered Wire Mesh Filter

-

OriginHebei China

-

Applicable IndustriesPower Plants, Steel Mills, Paper Industry, Industry, Chemical Industry, Food And Water Industry

-

MaterialSintered Mesh

-

Core ComponentsBackwash Filter

-

UsageLiquid Filter

-

Filter Media304 Stainless Steel Sintered Wire Mesh

-

Installation MethodVertical Or Horizontal

-

Filter Rating100

-

SizeCustom Production

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

4.0MPa 2000um Sintered Mesh Auto Backwash Strainer For Steel Plant

Automatic filter with high quality sintered mesh filter element in steel plant

Describe:

JSYL series equipment can filter out solid particles in various water and low-viscosity liquids (such as machined coolants), reduce liquid turbidity, purify water quality, reduce system dirt, bacteria, algae, rust, etc., and keep materials clean. In order to meet the requirements of system operation and downstream processes for liquid cleanliness, it can also be used to protect downstream key equipment from particle blockage, abrasion or fouling, and improve the operating efficiency and life of key equipment.

Features:

1. Fully automatic intelligent control

2. Small size, large flow, high precision

3. Intelligent online backflushing does not stop and flow continuously;

4. The body replaces the filter element, quick-plug design, easy to replace;

5. Multi-filter element structure; precision can be adjusted;

6. It can be installed vertically/horizontally, which significantly saves installation space

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Equipment model |

JSYL-JDX-ZD-DN(25-800) |

Cleaning method | Equipment's own filter element backwash |

| Shell selection | Carbon steel/stainless steel | Filter element form | Multi-layer woven mesh sintered |

| Single machine flow |

2-900 m3/h

|

Number of filter elements |

3-7 elements

|

| Rated pressure |

1.6MPa/2.5MPa/4.0MPa |

Filtration accuracy | 10-2000 μm |

| Applicable viscosity (cp) | 1-40cp | Applicable temperature (°C) | 0-95°C |

| Operation mode | Manual mechanical operation | Filter element replacement | Large cover flange replacement filter element |

|

Backwashing components

|

304 stainless steel | Filter element design | Cover replacement |

| Power unit | Compound reducer | Position proximity switch | Inductive |

| Backflushing node | Seven-star node disk | Pressure gauge | Seismic pressure gauge |

| Filter replacement cycle | Half a year/more than one year | Installation method | Vertical/Horizontal |

![]()

![]()

![]()