-

High Light

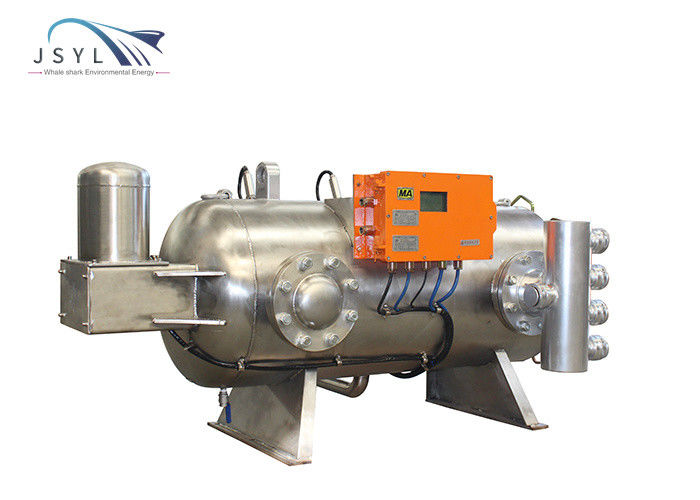

Backwash Mining Industry Water Filter

,OEM Mining Industry Water Filter

,25 Micron Liquid Return Backwash Filter

-

Product NameMining Water Filter

-

OriginHebei China

-

Applicable IndustriesManufacturing Plants, Industry, Agriculture, Energy And Mining

-

Warranty ServiceVideo Technical Support, Online Support Maintenance And Repair Services

-

Core ComponentsBackwash Filter

-

Warranty1 Year

-

Weight500-800KG

-

Equipment Size (L*W*H)1050*900*1000

-

Place of OriginHeBei China

-

Brand NameJing shark

-

Minimum Order Quantity1 set of

-

PriceNegotiable

-

Packaging DetailsSpecial carton and wooden case packing for export

-

Delivery Time15 days

-

Payment TermsT/T

-

Supply Ability10,000 units per month

OEM 25 Micron Backwash Mining Industry Water Filter

304 Material, liquid return backwash filter station

Working principle:

The same device can achieve three filtration precisions of coarse, medium and fine. The liquid enters the body through the inlet for filtration; impurities are deposited on the stainless steel filter screen, when the inlet pressure and the outlet pressure reach the preset value; the equipment recoil mode starts, and the high pressure precision The filter element is backwashed online; the backwashing node disk rotates 360 degrees; the online backwashing can be completed in 20 seconds, and the online backwashing will continue to flow without stopping the machine.

Features:

Few fragile contacts, low mechanical and manual maintenance costs; filter element is made of high-temperature special process multi-layer sintering, trumpet design, cleaning is more thorough, filter element replacement adopts quick-plug design, body replacement, operation is minimal; filtering accuracy is based on Need to switch at will, small size, large flow, high precision, non-stop and continuous flow during backwashing.

| PRODUCT PARAMETER | |||

| Specifications | Equipment parameters | Specifications | Equipment parameters |

| Device model | JSYL-HDX-ZD-KJ102/KJ126 (double in and double out) | Cleaning method |

The equipment itself backwashes the filter element |

| Shell selection | 304 material | Filter element form | 304 stainless steel sintered inverted mesh (high pressure filter element) |

| Single machine flow |

1000L/Min/2000L/Min

|

Number of filter elements |

A single unit comes standard with 7 high-pressure filter elements

|

| Rated pressure | 2.5-8.0MPa | Filter accuracy | 25 microns |

| Applicable viscosity (cp) | 1-40cp | Applicable temperature (°C) | -20-50°C |

| Operation mode | Fully automatic intelligent control/manual control | Filter element replacement | The body can replace the filter element in 15 minutes |

|

Pressure gauge

|

Seismic pressure gauge | Installation method | vertical/horizontal |

![]()

![]()

Applicable fields:

It is mainly used to filter the emulsion of hydraulic support underground in coal mines, filter out metal particles and rubber impurities of seals in the hydraulic system, and keep the liquid flowing back to the tank clean.